PRESS ROOM AUTOMATION releases its rst “3 in 1”, which combines a decoiler and astraigthener-feeder driven via servo motor. It targets manufacturers seeking a simple, robust and safe press feeding line with decent performances.

Features:

Decoiler

Decoiler with variable drive & loop control system.

3 or 4 jaw self-centring manual expanding mandrel of welded and stabilized steel.

Rotation jog mode from main control box.

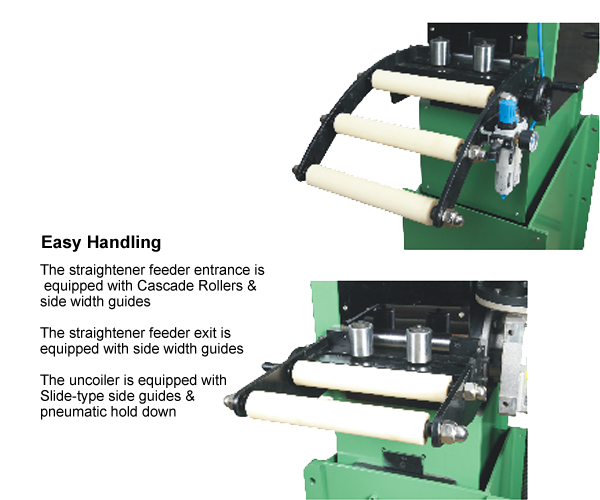

Pneumatic Hold-down (Optional snubber and peeler assembly for threading is available on request).

6 quick removable coil retaining arm-keepers, adjustable depending on the strip width.

NC Servo Straightener Cum Feeder

Stabilized Steel frame construction.

Cascade Rollers @ Entry.

Gear driven feed roll to ensure non-slip positive feeding.

Straightener Head consisting of 7 nos Straightening Rollers, 1 Pair of Pitch Roller & 1 Pair of Feeder rollers are provided at entry & exit respectively.

All upper rolls are individually adjusted with mechanical leadscrews and bevel gearings. The level of upper rolls penetration is shown by position indicators.

Power transmission to the other straightening rolls via precision spur gears.

Pneumatic actuated lifting of the set of upper rolls in synchronism with the forming machine to allow entry & self-centring of the strip when working with dies with automatic centering devices (pilot release).

Exit Width Guide Assembly.

Permanently sealed precision roll bearings, no lubrication required.

Motorisation through one brushless servo motor & precision gear box.

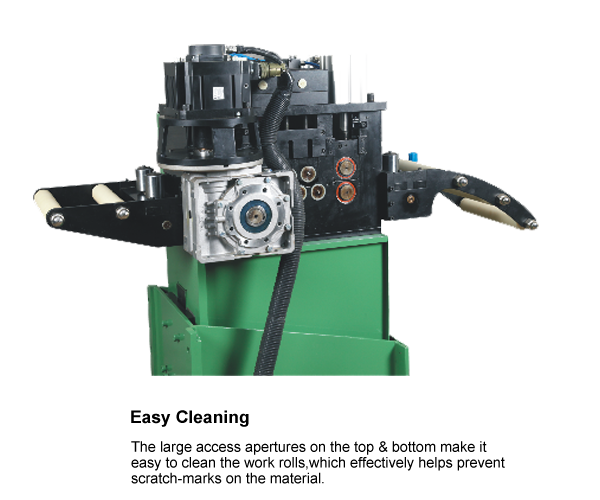

Crocodile opening of the head by lever, for safe & easy roll cleaning, and easy strip insertion.

Manual height adjustment by hydraulic jack +/- 50 mm of pass-line.

Features of Control Panel

Feed Length : 0 to 99999.999 mm

Speed : 1 to 50 mpm

Acceleration / Deceleration : 1 to 100%

Part number : 1 to 99

Length setting adjustment (from -0.1 mm to +0.1 mm) with 0.01 mm increment

Servo motor with built in resolver for feed measurement Press mode : single stroke or continuous operation

Feeder before Press (F-P) or Press before Feeder (P-F) selection

Main switch / Manual operation button / Emergency Stop

Manual jog programmed feed length for easier tool setting

Potentiometer for speed regulation of Decoiler

Diagnosis and display of error messages

Specifications :

Highend Fully Automatic Models with Coil Car, Hydraulic Jaw Expansion, Snubber, Peeler, Pre-Pinch, Auto Side Guide etc are available on request.

The above parameters are for the material having tensile strength 40kgf/mm² max. Models of higher capacity or higher or lower line speeds are available on request.

Technical specifications are indicative and subject to change to suit end application.