The main constructional characteristics of Press Room feeders are

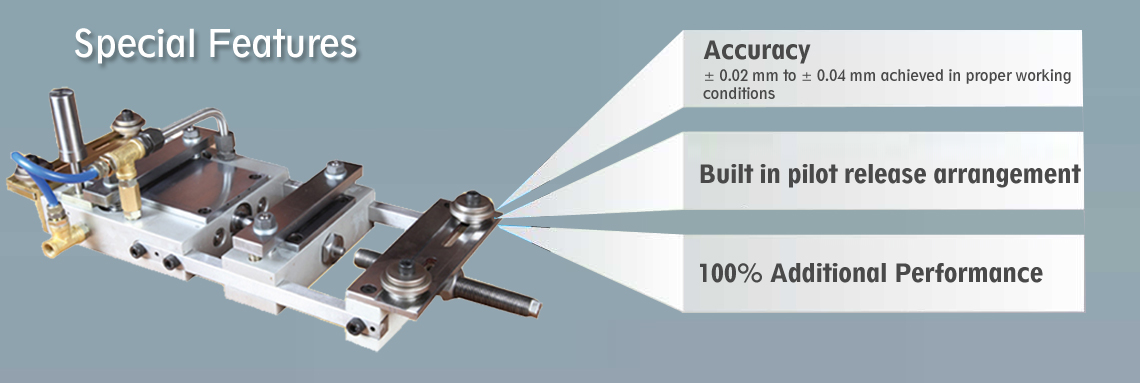

Pneumatic Feeders to meet new competitive challenges in Speed / Accuracy / Reliability / Longer life.

With an intense market research & practical experience in metal stamping based on regular market interaction, We have brought a range of Pneumatic Feeders to suit your exact requirement and application. Working on customer relations management theory, we offer a complete package of problem solving solution. Our field experience staff can help in setting your complete line & can guide you to select the perfect equipments & tooling.

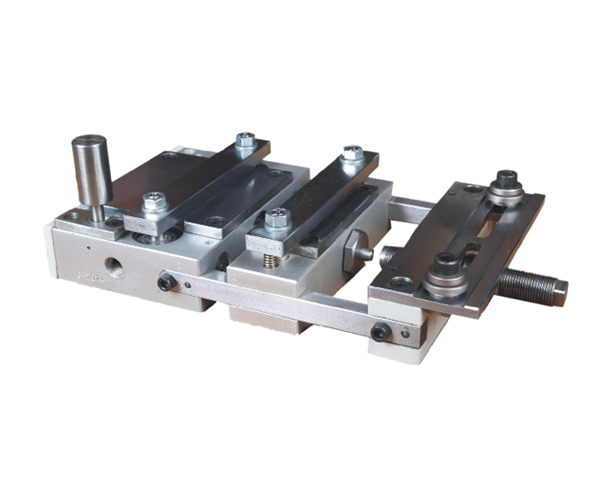

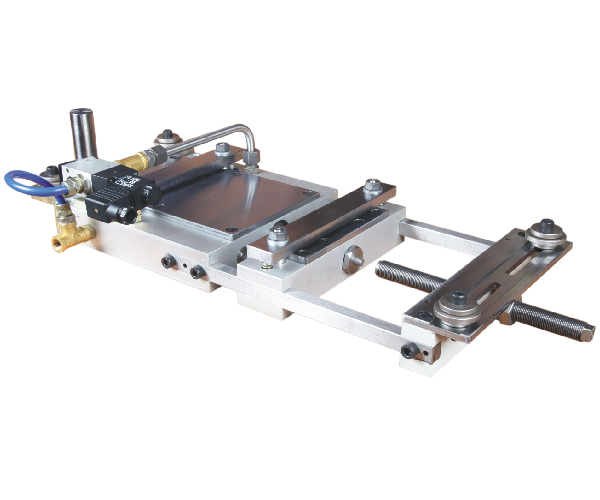

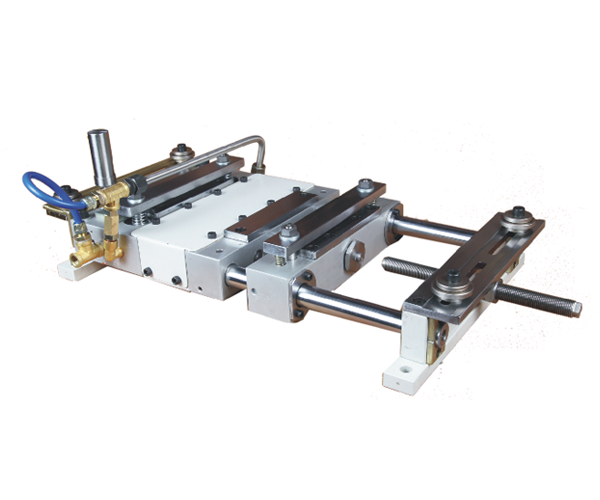

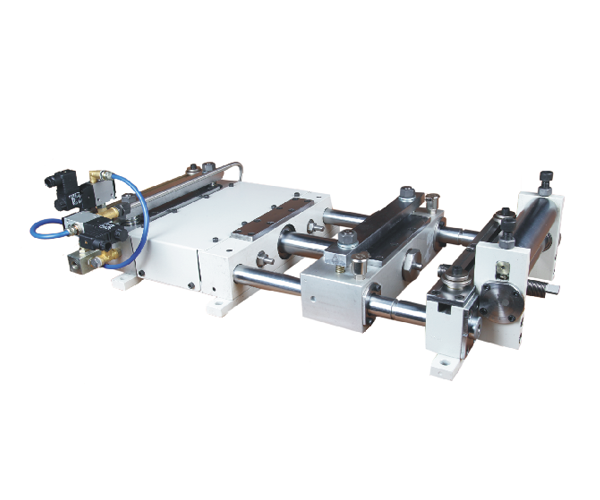

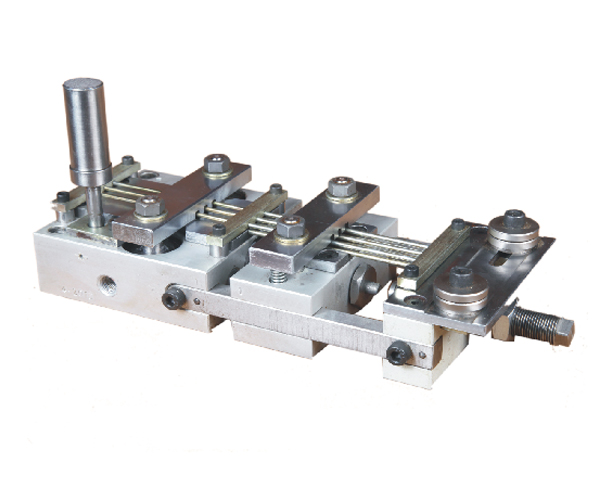

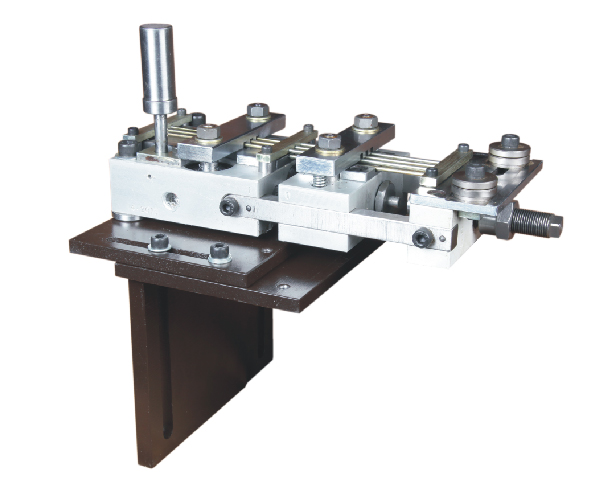

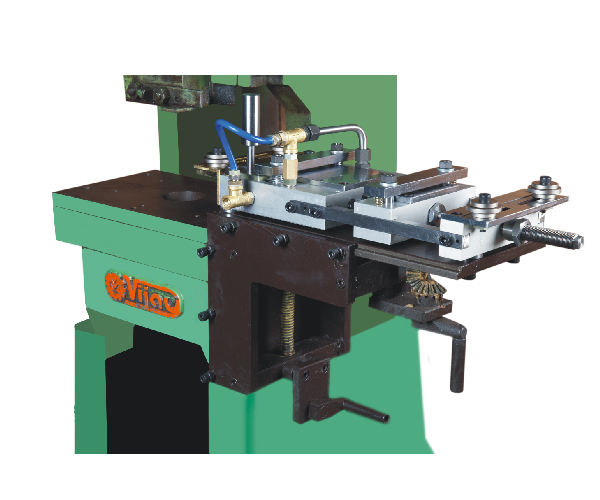

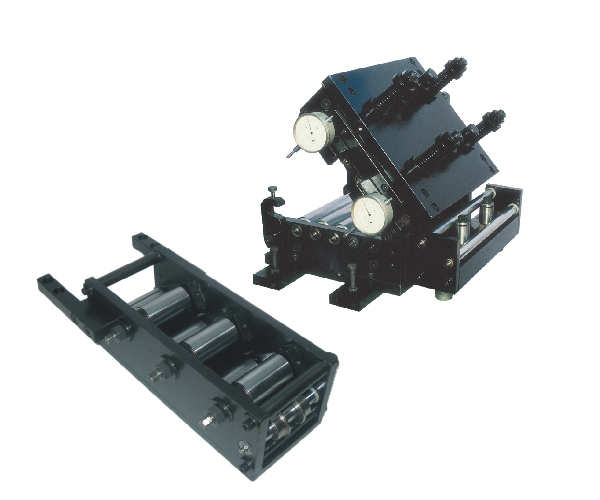

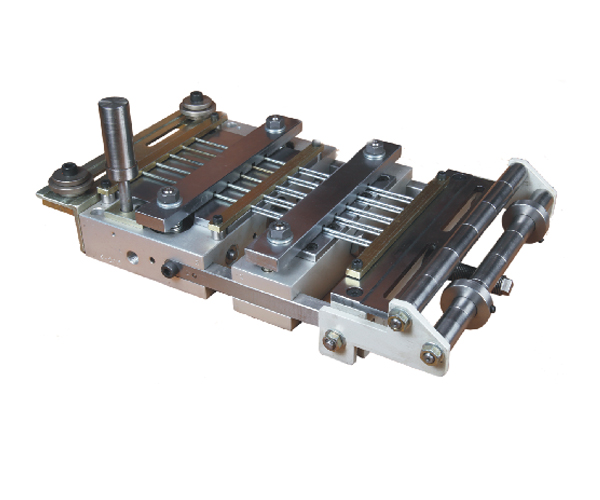

Press Room Pneumatic Feeders made from special alloy aluminium & are made in a modular way for automatic feeding of metallic & non metallic strips including paper, plastic, fiber, wires, tubing, extruded material.Technically advanced design, selection of finest material, combined with strict quality control manufacturing, has resulted in most reliable air feeds for Indian Tough Condition. Models available uptill 600mm wide, 5mm thick, 600mm pitch / stroke length.

Models of Air feeder / Pneumatic Feeder for Press feed Equipment

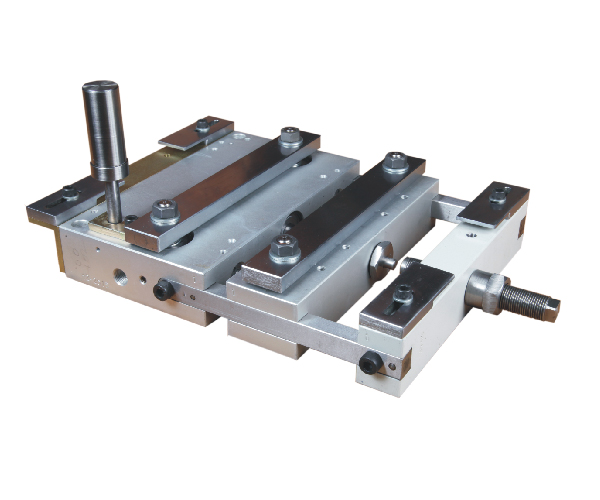

Light Series (LS) |

|||||||||

Max width in mm |

Max Width |

Max Stroke |

Max Stroke |

Max Stroke |

Pressure |

Pressure |

Traction |

Total |

Weight Kg. |

LS 50 x 50 |

50 |

50 |

1 |

220 |

44 |

92 |

19 |

0.18 |

4.750 |

LS 100 x 50 |

100 |

50 |

0.5 |

200 |

44 |

92 |

19 |

0.18 |

6.750 |

Mid Series (MS) |

|||||||||

Model |

Max Width |

Max Stroke |

Max Stroke |

Max Stroke |

Pressure |

Pressure |

Traction |

Total |

Weight Kg. |

MS 50 x 50 |

50 |

50 |

2.0 |

200 |

65 |

137 |

35 |

0.28 |

7.5 |

MS 100 x 100 |

100 |

100 |

1.8 |

140 |

65 |

137 |

35 |

0.56 |

11.5 |

MS 100 x 150 |

100 |

150 |

1.6 |

100 |

65 |

137 |

35 |

0.84 |

14.0 |

MS 150 x 50 |

150 |

50 |

1.8 |

140 |

65 |

137 |

35 |

0.28 |

10.5 |

MS 150 x 150 |

150 |

150 |

1.5 |

100 |

65 |

137 |

35 |

0.84 |

17.0 |

MS 200 x 100 |

200 |

100 |

0.7 |

80 |

65 |

137 |

35 |

0.56 |

20 |

MS 300 x 100 |

300 |

100 |

0.5 |

80 |

65 |

137 |

35 |

0.56 |

23.5 |

Extra Mid Series (EMS) |

|||||||||

Model |

Max Width |

Max Stroke |

Max Stroke |

Max Stroke |

Pressure |

Pressure |

Traction |

Total |

Weight Kg. |

EMS 100 x 100 |

100 |

100 |

2.5 |

140 |

65 |

137 |

40 |

0.77 |

18.5 |

EMS 150 x 150 |

150 |

150 |

2.0 |

100 |

65 |

137 |

40 |

1.54 |

23.0 |

EMS 225 x 200 |

225 |

200 |

1.2 |

80 |

65 |

137 |

40 |

1.73 |

30.0 |

EMS 300 x 300 |

300 |

300 |

0.5 |

60 |

65 |

137 |

40 |

2.31 |

37.0 |

| EMS 400 x 100 | 400 | 100 | 0.7 | 80 | 65 | 137 | 40 | 0.77 | 42.5 |

| EMS 600 x 100 | 600 | 100 | 0.5 | 80 | 65 | 137 | 40 | 0.77 | 51.0 |

Extra Mid Series (EMS) |

|||||||||

Model |

Max Width |

Max Stroke |

Max Stroke |

Max Stroke |

Pressure |

Pressure |

Traction |

Total |

Weight Kg. |

EMS 100 x 100 |

100 |

100 |

2.5 |

140 |

65 |

137 |

40 |

0.77 |

18.5 |

EMS 150 x 150 |

150 |

150 |

2.0 |

100 |

65 |

137 |

40 |

1.54 |

23.0 |

EMS 225 x 200 |

225 |

200 |

1.2 |

80 |

65 |

137 |

40 |

1.73 |

30.0 |

EMS 300 x 300 |

300 |

300 |

0.5 |

60 |

65 |

137 |

40 |

2.31 |

37.0 |

| EMS 400 x 100 | 400 | 100 | 0.7 | 80 | 65 | 137 | 40 | 0.77 | 42.5 |

| EMS 600 x 100 | 600 | 100 | 0.5 | 80 | 65 | 137 | 40 | 0.77 | 51.0 |

Heavy Series (HS) |

|||||||||

Model |

Max Width |

Max Stroke |

Max Stroke |

Max Stroke |

Pressure |

Pressure |

Traction |

Total |

Weight Kg. |

HS 100 x 100 |

100 |

100 |

4.0 |

100 |

126 |

757 |

120 |

2.2 |

39.0 |

HS 200 x 200 |

200 |

200 |

3.0 |

60 |

126 |

757 |

120 |

4.5 |

57.0 |

HS 300 x 300 |

300 |

300 |

2.0 |

40 |

126 |

757 |

120 |

6.75 |

76.0 |

HS 400 x 400 |

400 |

400 |

1.5 |

25 |

126 |

757 |

120 |

9.0 |

95.0 |

Air Pressure Required : 5 - 8 Bar

Note : Extra Mid Series & Heavy Series Feeders Due To Modular Manufacturing System Can Be Easily Modified To Bigger Feeding Lengths (100 / 200 / 300 / 400mm)

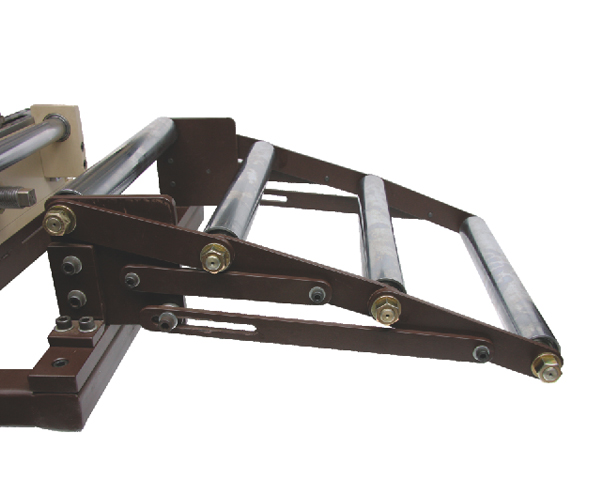

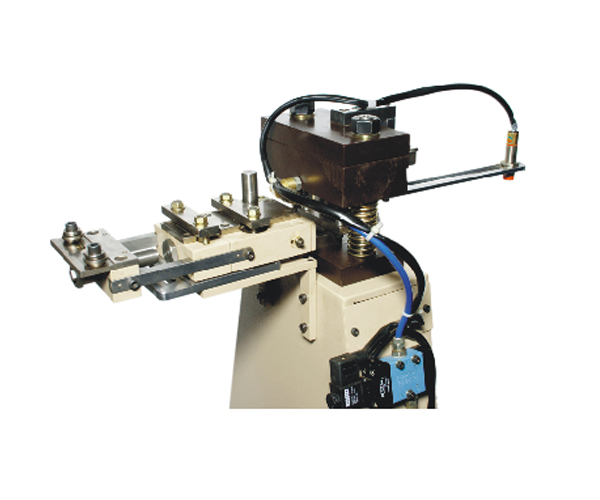

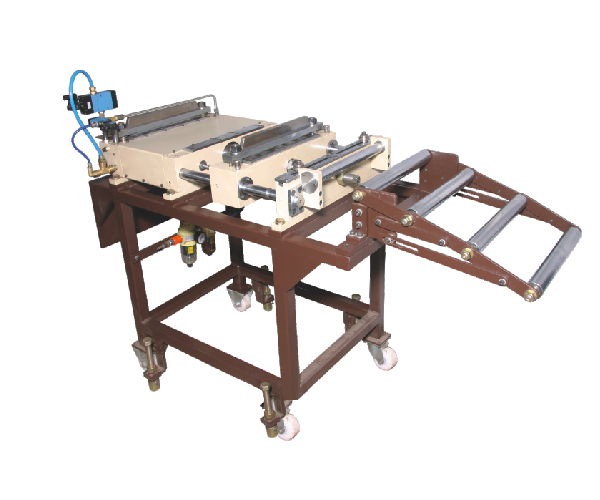

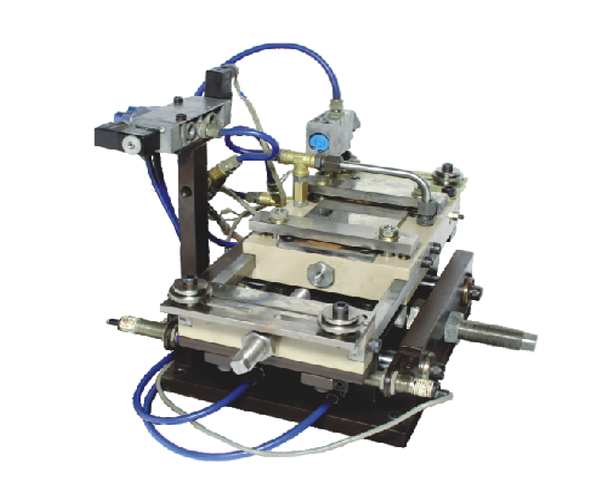

Optional Attachments for Air Feeder / Pneumatic Feeder

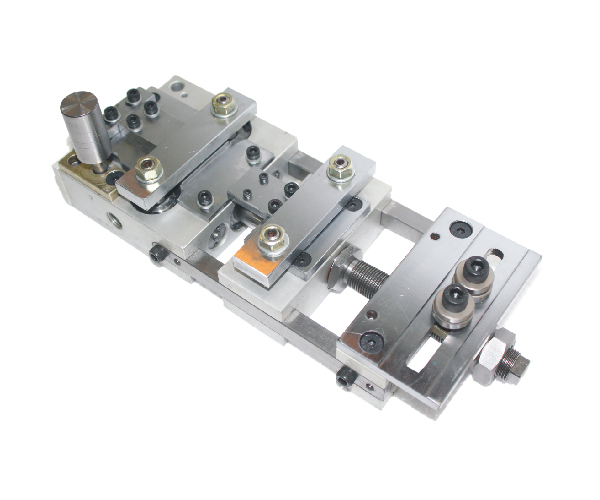

Feeders for Different Applications

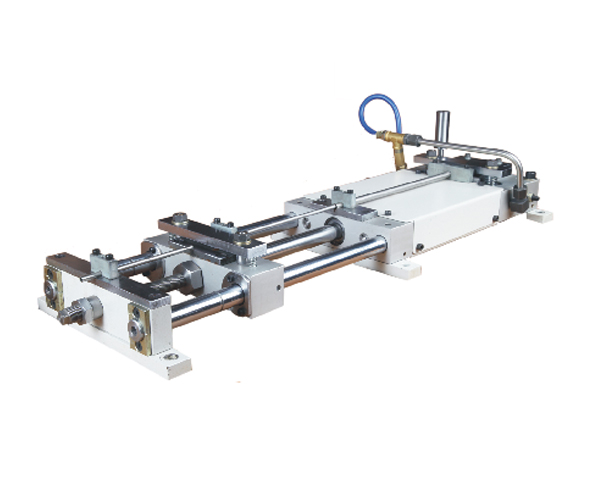

Pneumatic Feeder With Remote Actuation and Pneumatic Decoiler For Copper Components Line

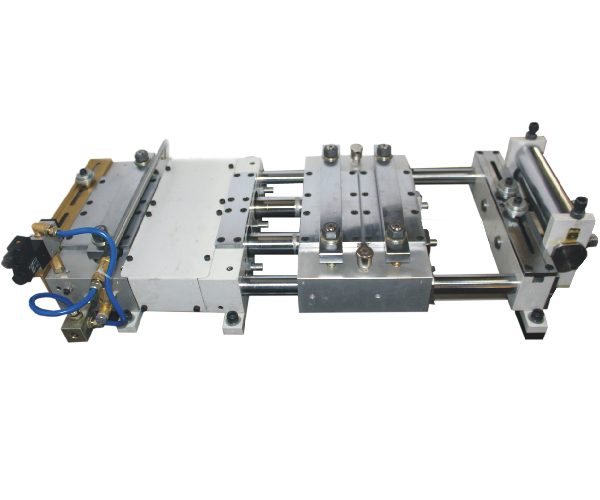

Pneumatic Feeder for Sectional Feeding

Pneumatic Feeder with Guiding Device and Remote Actuation

Push Pull Pneumatic Feeder, Push Pull Pneumatic Feeder manufacturer

Pneumatic Feeder

Pneumatic Feeder for Sectional Feeding

CRADLE UNIT WITH PNEUMATIC FEEDER & RECOILER | Press Room Automation

High Speed Pneumatic Feeder, High Speed Pneumatic Feeder