ABOUT US

WE ARE TEAM PRESS ROOM AUTOMATION Our purpose is to create simple automation system in coil processing industry with proper design, excellent manufacturing, stringent quality control, and skilled installation. With more than 30 years of experience in the field of press automation, Press Room Automation is today able to satisfy many productivity needs and offer a production solution to meet the customer's specific requirement. We bring in the best expertise and the most spread out industry network.

We are 100% focused on designing and constructing of a series of automated machines for sheet metal working and are proud to have installed more than 6000 equipments all over the world. We provide best Application Engineering & Prompt after Sales service throughout the country. Over the last 5 years, the Company had already tied-up with International giants for offering on complete technological solution in future automating the sheet metal component manufacturing.

Thanks to our computerized technical office, Press Room is able to track the order from the planning phase to design, manufacturing, warehouse management and installation. Utilizing our 2D/3D CAD system not only are these functions performed but also inventory control. Press Room utilizes CNC and FMS machine tools with latest technology capable to of producing component with tight tolerance.

Most Trusted Range

Ready Stock Available at Our Factory

Range of Decoiler, Compact / Cradle Type Decoiler Cum Straightener, NC Servo Feeder & Pneumatic Feeder

Infrastructure

We continuously upgrade our infrastructure to match the latest in technological advancements. This includes the best manufacturing machines with the most accurate measuring instruments and techniques.

We have 2 manufacturing plants one machine shop with CMM inspection facilities & other is assembly plant.

Design

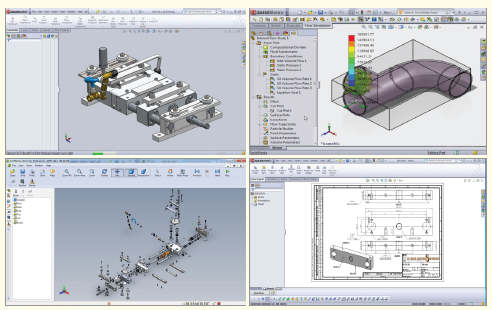

We uses latest softwares like SolidWorks to design, test against real world conditions & get the same into production quickly & efficiently. Part Modelling & Detail Engineering Drawing is done using Solid Works or Briscad. Complete 3D assembling & interference checking is done using Solid Works Assembly. Detail Exploded View & e-Drawings Conversion (for customers) so that maintenance & required spares can be ordered without any downtime. Detail FEA analysis is done using SolidWorks Simulation & Flow Simulation. We do CNC Programming using CAM software like MasterCAM. With in House CMM facilities available with PC Dmis software having CAD import facilities, we are able to generate all the inspection programs offline. All critical components are inspected within very tight tolerance.

Software Capabilities

After Sales Service

All spares parts readily available incase of any breakdown / service requirements.